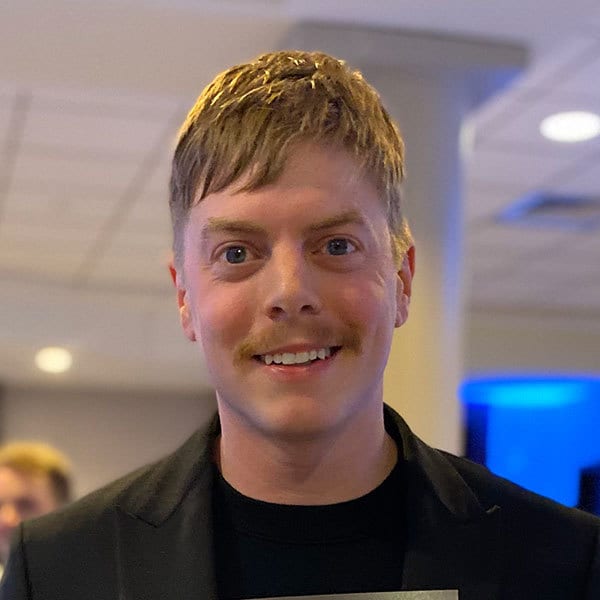

Next Gen All Star: Sam Revel

Age: 34

Company: Pitt Meadows Plumbing & Mechanical Systems

Title: Director of industrialized construction

How long have you been in the PHCP-PVF industry?

SR: I started work in plumbing at the age of 15 in the UK on my summer break, this was mostly work experience in residential and mechanical rooms in central London. I started a plumbing course at 16 out of high school, then continued into an apprenticeship, starting when I was 17. Once I had my apprenticeship complete, I moved into the office and started on a project manager track including a bachelor’s degree in Building Services Engineering.

I moved to Canada in 2016 and have worked with PMP as a project manager, moving into senior management in 2017 before becoming a director in 2023

What drew you into the industry?

SR: I kind of fell into it. I’ve always worked in construction, I spent my adolescence fixing up houses with my Dad and working for his construction business. I did work experience at a structural engineer and had plans to pursue architecture, but when I went to sign up for college, they had no tutor for the course, so I went for plumbing instead.

What is the most rewarding aspect of working in the industry?

SR: For me, it’s seeing a long term plan come together, when you truly plan a project and then three or four years later everything falls into place it’s so rewarding.

What motivates you every day?

SR: Solving complex problems and pushing the industry forward with industrialized construction. We’re seeing a huge shift in the construction industry and technology disrupts everything we do. PMP is at the forefront of that transition.

We invested heavily in BIM, off-site manufacturing, robotics and automation over the last six years and that’s taken a lot of time and effort to implement, but when you see the improvements it’s giving the company it keeps you motivated.

What is one thing you wish more people knew/understood about the PHCP-PVF industry?

SR: The opportunities in the construction sector are huge, if you put in the time and do great work the career progression is exponential. I’m loving watching the trades become a saught after career again, growing up it wasn’t considered a great life plan, but that has changed over the last few years.

What has been the proudest moment in your career so far?

SR: It definitely changed over my career, when I started, I wanted to be able to take a project from design to handover. I was lucky enough to do that, completing a project in 2020 that I help design, bid, then project manage and handover. We did it during the pandemic, on time and under budget. That felt like a huge milestone. In the last few years, it’s been one of becoming a good manager and mentor, my role has transitioned and I’ve been working hard to develop the people in my team, ensuring their careers are successful.

What is one thing most people don’t know about you?

SR: I love woodworking, I always have some projects on the go, and love to work with my hands whenever I get the time! That normally means 30 minutes at a time around everything else going on!

Why he was chosen as a Next Gen All Star Top 20 Under 40 winner:

“Sam has been pivotal at Pitt Meadows Plumbing in our industrialized construction journey. He's passionate about constantly innovating the pre-fabrication model as showcased in our #FabricationFriday posts each week. He gives weekly tours to other industry partners to show how our 3D modeling software integrates with automated smart tools to fabricate assemblies needed for more than 15 different project sites.

“Pitt Meadows Plumbing & Mechanical is known within the Vancouver construction industry for being innovative and passionate about industrialized construction. There are many challenges with the future of the skilled trades and Sam has been vocal about how we as a company can continue to drive innovation to work on solving some of these key challenges.

“One of the most exciting projects we worked on and saw Sam’s skill in collaboration on was the Royal Inland Hospital Project. He worked with senior project manager, Shalana Morton, and other trade partners to arrange the design, fabrication and installation of 56 Multi-Trade Racks. Because of this concerted collaboration, the decision was made to install these complex systems before steel studs and door frames, which allowed installation to be streamlined. MTR installation was 100% complete over three floors with four weeks of the final concrete slab having the shoring removed.” — Sara Searle, Pitt Meadows