Bilanol / iStock / Getty Images Plus

Learn how advanced centrifugal grinder pump design addresses common performance and maintenance hurdles.

by Andy Freberg

The most efficient type of grinder pump is one that professionals can install and never have to touch for maintenance or repairs. It manages solids seamlessly without clogging, keeping residential, low-pressure sewer, industrial, commercial, or municipal wastewater systems up and running. It stands up to the modern “flushable” products that often wreak havoc on systems. It also offers the fluid velocity needed to pull solids into the cutting mechanism and effectively pass them instead of allowing them to settle in the bottom of the tank.

When evaluating the merits of a grinder pump, contractors and engineers must consider the pump’s inlet and discharge velocity, grinding mechanism, and how other value-added features can deliver long-term benefits and maximum uptime for wastewater management.

Centrifugal grinder pumps with radial cutting mechanisms check all the right boxes when it comes to delivering the features needed for reliable performance. With stronger fluid velocity and cutting power than positive displacement pumps or axial-cutter models, they tackle the toughest challenges facing modern wastewater systems:

Challenge: Clogging at inlet or discharge

Solution: Better fluid velocity

Debris settling in lines or getting stuck at a pump’s intake are major concerns for wastewater operations. When solids are not drawn into a grinder pump’s cutting mechanism, it is a sign of a weak inlet velocity. This is a common issue with positive displacement pumps, which have lower fluid velocity on the discharge. This can result in solids accumulating against the intake, tank edges, and sewer line.

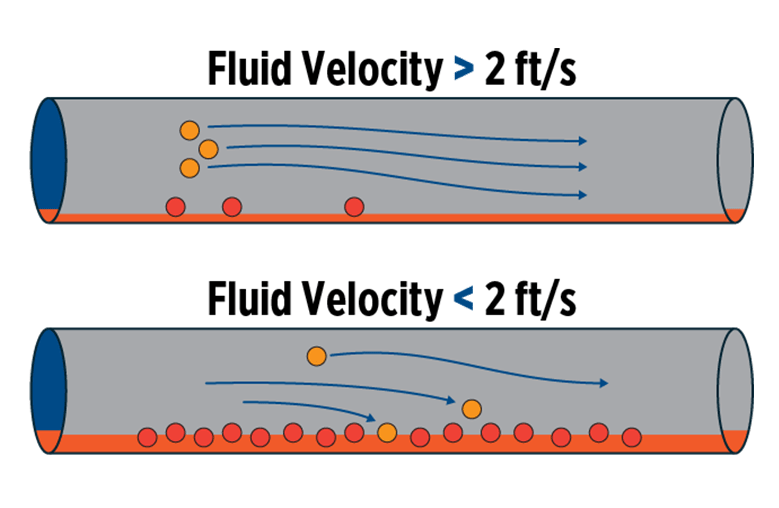

The EPA’s Alternative Wastewater Collection Systems manual states a fluid velocity with a minimum of two feet per second is required to scour solids in a low-pressure sewer line. Once fluid velocity drops below 2 ft/s, solids are prone to accumulate along the bottom of the pipe.

Centrifugal grinder pumps provide superior fluid velocity when compared to positive displacement grinders, keeping solids in suspension within the sewer system. These pumps are also designed to deliver this performance without generating cavitation or limiting the operating range.

Higher fluid velocity advances solids in suspension. Once fluid velocity drops below 2 ft/s, solids are prone to accumulate along the bottom of the pipe.

Challenge: Cutter binding

Solution: Radial cutters

Centrifugal grinder pumps can come equipped with axial or radial cutting systems. Axial cutters can struggle with fibrous materials, especially as shear gaps increase. Over time, the distance between the cutters will open, allowing premature failure or clogging to occur.

Radial cutting mechanisms are cast parts designed to shred materials with a rotating and stationary cutter. Unlike other systems, they don’t rely on wear parts to establish the shear gap. Instead, they provide higher shearing force and retain tighter tolerances over time. This makes them a better choice than axial cutters, which require ongoing adjustment throughout the pump’s life. With axial cutters, separation over time creates resistance in the tension zone because the material doesn’t break in shear.

ADVERTISEMENT

A powerful centrifugal grinder motor torque is also critical for griding material – especially when the pump is in a locked rotor condition. Higher locked rotor torque from the motor results in a higher shearing force applied by the cutters. This ensures that incoming solids, including difficult fibrous materials, are drastically reduced assuring successful passage.

High force and tight shear are key to managing the stringy solids and fibrous materials found in today’s wastewater streams. When choosing a centrifugal pump, look for a floating radial cutter paired with a powerful motor to get the performance needed to grind tough materials while providing the shear required to pulverize the waste.

Reducing L (distance between the shear surfaces) while maintaining the same δ (movement of the rotating cutter away from the stationary cutter) increases shear strain γ (γ = tan-1(δ/L). This increases shear stress on the material to allow successful passage.

Challenge: High cost of ownership

Solution: Quality design and components

Centrifugal grinder pumps must exert enough force to shred difficult materials, and the pump motor shaft must be able to withstand radial loads without bending. A shorter motor shaft reduces the leverage a radial load places on the bearings, while greater thickness gives the shaft more cross-sectional area to resist deflection. Both of these traits are critical to withstanding shaft deformation and premature motor or bearing failure in grinding applications.

Axial cutters usually establish a shear gap with shims. These can shift during operation, causing wear and reduced grinding efficiency. In contrast, radial cutters are cast with tolerances set and provide the cutting performance needed so maintenance teams don’t have to pull the pump to adjust for proper clearance.

Challenge: Motor damage due to binding at cycle end

Solution: Longer run cycle

Cycle ends can be challenging for grinder pumps, which often get material lodged in the cutting mechanism. When the cycle restarts, the material will become wedged between the cutters and bind the system. A floating radial cutter tackles the issue, but minimizing starts and stops is the real key to smoother operation.

Centrifugal grinder pumps usually have longer run cycles with increased flow to clear more waste in less time than positive displacement pumps. Longer run cycles with fewer starts and stops extend pump life by reducing wear on the start components.

Franklin Electric’s industry-leading two horsepower IGP Series grinder features a patented floating cutting system that delivers peak locked rotor torque.

Challenge: Roping due to non-dispersible solids

Solution: Notched components

Roping occurs when long, fibrous materials get tangled together, forming rope-like strands that can clog pipes and impede the function of pumps. Stringy materials often wind around the grinder blades or along the pump shaft. When the cutting surfaces cannot break a continuous stream of matter, the material will wrap around the shaft between the rotating and stationary cutters or around the shaft seal.

To overcome this challenge, look for cutters and volutes that include notches. These notches help distribute the flow of materials against the cutters, balancing the pressure to minimize radial forces that contribute to roping.

Centrifugal grinder pumps with the right features make all the difference in uptime. Durable construction and radial cutters mean stronger fluid velocity, greater shear force, and more reliable performance. The result: longer run cycles, improved efficiency, and lower overall cost of ownership.

Photos courtesy of Franklin Electric

Andy Freberg is the Senior Product Specialist, Industrial Wastewater at Franklin Electric.