High-end DHW issues

The Glitch:

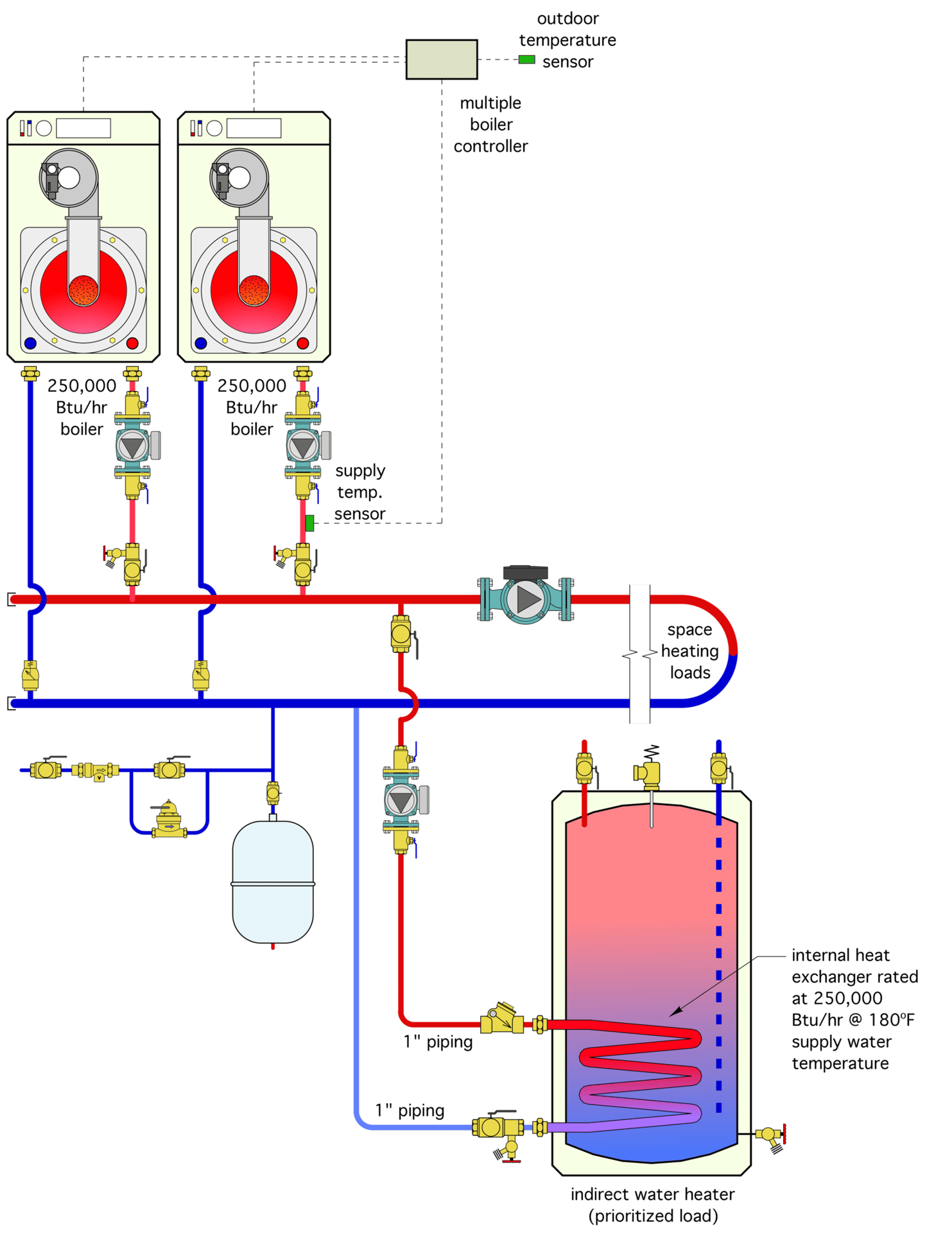

The system shown in Figure 1 was installed to provide domestic hot water to a high-end house with several bathrooms. The installer selected the largest 119-gallon indirect water heater available from his supplier. The tank’s internal heat exchanger was rated to transfer 250,000 Btu/h when supplied with 180° F water from the boiler. He piped it in with 1-inch copper tubing because that was the size of the piping connections on the tank. He used three identical zone circulators, one for each boiler, and one for the indirect tank. He used a larger circulator for flow to the space heating portion of the system.

Being concerned about a potential complaint about not enough hot water, he convinced the owner to double up on boiler capacity, and thus installed two boilers, each rated at 250,000 Btu/h. He also set the internal high-temperature limits on each boiler for 200° F during a call for domestic water heating (because that’s as high as the control would go). He assumed that 200° F water through the coil will significantly increase the heat transfer through the tank’s coil heat exchanger.

When put in operation, the system experienced serious problems. The 15 gpm shower in the master bathroom only remained comfortable for about five minutes, followed by a rapid drop in water temperature. The boilers also short cycle and emit “knocking” sounds during the domestic water heating mode. Even worse, the house quickly overheats each time there was a call for domestic water heating.

Can you spot at least five details that are incorrect, and recommend how to fix this situation?

ENLARGE

Are you an ace troubleshooter?

Within the pages of this magazine, PM’s Hydronics Editor John Siegenthaler, P.E., will pose a question to you, our readers, to review a system’s schematic layout and discover its faults, flaws and defects. Discover archived “The Glitch & The Fix” exercises at its radiant-focused website, www.radiantandhydronics.com. Good luck!