PHCC’s Copp announces retirement

Michael Copp, executive vice president of the Plumbing-Heating-Cooling Contractors — National Association, formally announced that he will retire from PHCC in December.

“We appreciate the many significant contributions Michael made for the organization over the past six years,” PHCC President Hunter Botto said. “Thanks to his leadership, PHCC made considerable progress in fulfilling important strategic goals and positioning PHCC members as the ‘contractors of choice’ in their markets. The association is now well positioned to achieve sustained growth and further our mission of advancing the industry through education and training to protect public health, safety and the environment.”

Botto praised Copp for leading important future-focused strategic initiatives, as well as accelerating the implementation of effective new technologies and processes that enabled the PHCC national office to remain fully operational throughout the COVID-19 pandemic and provide members with relevant and timely resources to weather the storm and prepare for the next normal.

During Copp’s tenure, PHCC achieved many legislative and regulatory successes to benefit professional plumbing, heating and cooling contractors; made progress on important workforce development initiatives; expanded HVAC-specific resources and collaborative efforts; elevated marketing efforts and began producing a quarterly magazine; built a new education and training department; launched several online member communities; offered numerous new member benefits; and realigned and strengthened its relationships with PHCC industry partners and coalitions, the association noted. The organization also updated the association’s history book, “A Heritage Unique,” and finalized a crisis action/pandemic plan that was offered as a model for PHCC chapters and members during the pandemic.

“It has been an honor and privilege to serve our PHCC members and work with so many great professionals across the PHCC federation over these past six years,” Copp said. “Our collective efforts represent a real team effort; especially these past two years, which proves that PHCC members and staff continue to move forward with hope in their eyes and a bone in their teeth as they protect the health and safety of everyone and our planet.”

A PHCC search committee has been formed that will work with a consultant to begin the process of identifying and interviewing possible successors. PHCC’s leadership is committed to hiring an individual with the skills and drive to ensure the association’s continued growth and member success, the association said. Interested candidates may contact Susan at recruiter@appliedvisionworks.com.

ServiceTitan continues expansion

ServiceTitan, a provider of software for the trades industry, announced it will open an office in the greater Salt Lake City region to fuel the company’s rapid growth and pursuit of strong technology talent. As the company’s fifth office location, the Salt Lake City office will serve multiple functions, including a Global Center of Excellence for ServiceTitan customer support. ServiceTitan also announced it brought on Kim Park, vice president of global customer support, to lead the company’s initiative to hire customer experience talent in the region.

“Making our customers wildly successful is core to our DNA at ServiceTitan. It drives every decision we make from our products to our services and beyond,” said Ara Mahdessian, CEO and co-founder of ServiceTitan. “In this case, I’m particularly excited to bring Kim Park aboard and to launch our Customer Support Global Center of Excellence so that we can continue to serve our customers at the level they deserve.”

As a longtime Utah resident, Park brings more than 15 years of experience growing and scaling world-class customer support organizations in the Salt Lake City region.

“I’m proud to join ServiceTitan to lead the customer support team into the future,” Park said. “Our primary focus is on our customers’ success, and the investment of the new Center of Excellence in Salt Lake City is a powerful declaration of our commitment to them. I have lived and worked in the customer support industry in Utah for several decades, and look forward to bringing on exceptional talent to help us elevate our customer experience.”

This past March, ServiceTitan announced a $500 million round of investment at an $8.3 billion valuation, making it the highest-valued private vertical software company in the world, the company noted. ServiceTitan also announced that it surpassed $250 million in annual recurring revenue, having grown 10 times in the last three years. With more than 1,600 employees worldwide, ServiceTitan has been named one of the best places to work by Inc. and the Los Angeles Business Journal for three straight years.

ASC Engineered Solutions acquires Trenton Pipe Nipple

ASC Engineered Solutions has acquired Federalsburg, Maryland-based Trenton Pipe Nipple Co. Trenton Pipe Nipple Co. produces and supplies brass and stainless nipples, fittings and pipe to industrial pipe, valve and fittings markets. In addition, the company’s custom fabrication capabilities will enable ASC Engineered Solutions to handle special customer requests for certain pipe nipples.

ASC Engineered Solutions’ CEO Jason Hild said, “We expect that the addition of Trenton Pipe Nipple will strengthen our organization’s ability to provide differentiated solutions to our customers.”

“We are excited to have the additional product breadth, knowledgeable team members and distribution partners that Trenton Pipe Nipple brings to us,” said Dean Taylor, ASC Engineered Solutions executive vice president. “I would personally like to thank Steve Holloway, past owner of Trenton, for his dedication to our industry and wish him well as he transitions into retirement. Steve will provide consultative support through the integration.”

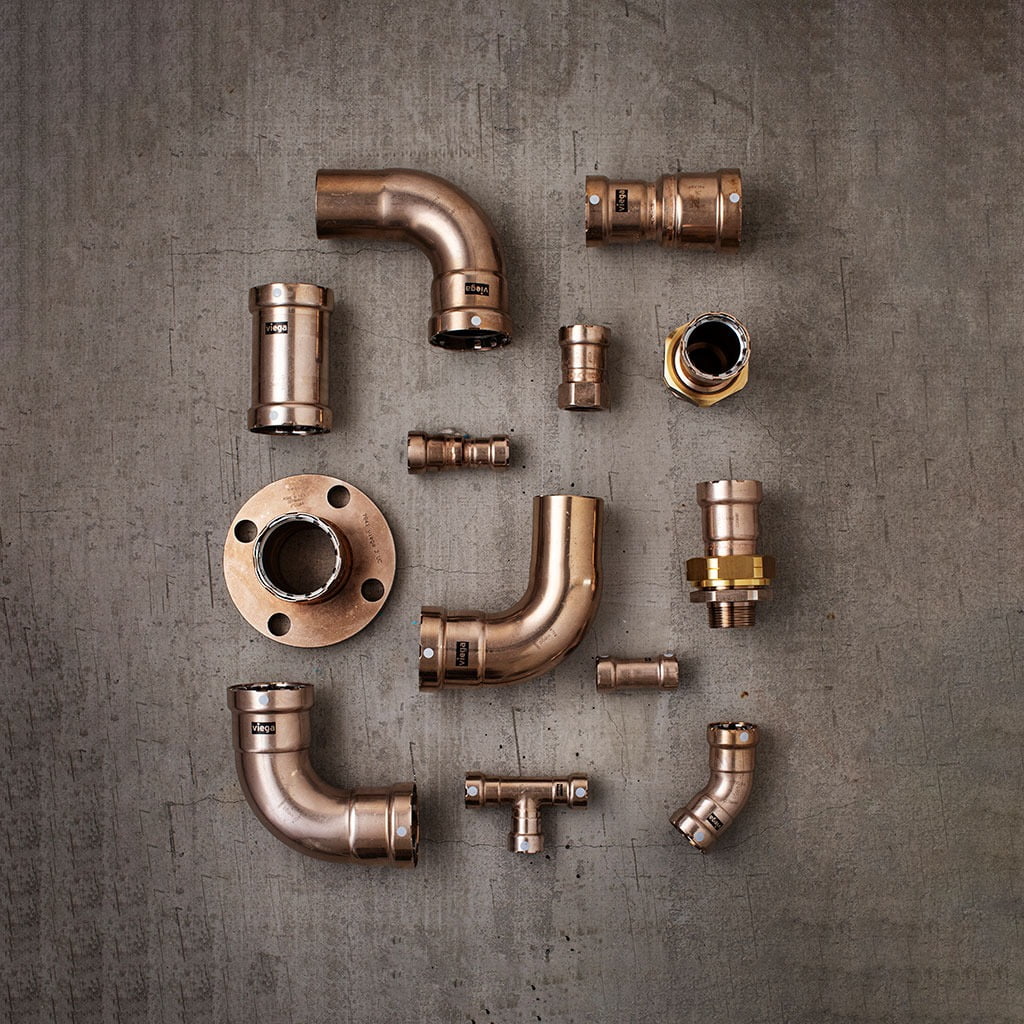

Viega products receive Navy approval

Viega MegaPress CuNi and ProPress copper fittings are the first press fittings approved for use in Navy combat ships.

After years of rigorous testing, the Naval Sea Systems Command (NAVSEA) has approved the use of MegaPress CuNi mechanically attached fittings in sizes 1/2-inch to 2 inches in surface combatants for a variety of systems, including chilled water, potable water, electronic freshwater cooling, seawater cooling, washdown countermeasures, drainage and many others. ProPress copper 1/2-inch fittings were also approved for potable water and various drains.

“NAVSEA is arguably the toughest standard in the world, and earning that approval has been a longtime goal of Viega,” Viega Director of Marine TJ Tracy said. “It’s an affirmation of just how reliable and durable our fittings are in even the most demanding circumstances.”

Pressing pipe offers the Navy, its shipyards and contractors two enormous benefits, Viega noted.

The first is mitigation of fire. Fire is one of the greatest dangers in ship construction, repair and maintenance. There were more than 600 shipboard fires documented between 2017 and 2020. A recent analysis by the Society of Naval Architects and Marine Engineers found more than half of the fires were caused by hot work, such as welding and soldering.

In July 2020, welding sparks ignited small fires on Navy ships at two separate shipyards. Though they were quickly extinguished, the fires prompted work shutdowns while safety measures were reviewed. That same month, the amphibious assault ship Bonhomme Richard burned for four days while pierside in San Diego. Repairs were estimated to take six years and cost $3 billion, so the Navy was forced to decommission the ship 18 years ahead of schedule.

Because pressing does not require heat, flame or an external power source, it eliminates the danger of fire when joining pipe, Viega explained. It also makes it unnecessary to post a fire watch or to prepare a jobsite for hot work.

The second benefit is cost and labor savings, Viega added. Pressing can reduce installation time by 70% over traditional methods of joining pipe, the manufacturer stated. When coupled with savings when testing the systems, due to near-zero leaks, the cost and schedule advantages easily outweigh the investment, Viega stated. The National Steel and Shipbuilding Co. (NASSCO), which builds Navy ships, has done studies showing that testing pressed pipe fittings costs less due to fewer leaks, repairs and retesting.

“Viega has been helping commercial marine and other industries benefit from pressing for years, and we’re excited to bring that technology to our defense partners. We’re proud and confident that our fittings will make pipe joining safer, faster and more efficient on Navy ships,” Tracy said.

The primary NAVSEA-approved fitting is MegaPress CuNi, a 90/10 copper nickel alloy specifically designed to withstand harsh marine environments. It can be used on Schedule 40 and Class 200 90/10 copper nickel pipe. The second is the ProPress copper fitting system, which offers more than 400 different configurations and three different sealing elements: EPDM, FKM and HNBR.

The Navy approval is only the latest marine-related approval for Viega products. The U.S. Coast Guard, American Bureau of Shipping, DNV-GL, Lloyd’s Register, Bureau Veritas and RINA all have previously approved the use of Viega fittings in marine environments.

Bradley announces executive team promotions

Bradley Corp. announced several promotions within its executive team, including Jon Dommisse, Nate Kogler and Mark Umhoefer.

Dommisse has been promoted to vice president of marketing and corporate communications. Over his 25 years with Bradley, Dommisse has led marketing, product management and corporate strategy. He will focus on expanding the reach of Bradley’s globally recognized brand, strategic planning, and supporting acquisition and partnership initiatives.

Kogler has been promoted to vice president of products and engineering. In his 20 years with Bradley, Kogler has progressed through the product management organization. His focus is on driving new product development and product strategy.

Umhoefer has been named chief financial officer. Formerly vice president of finance, Umhoefer has been with Bradley since 1993 and has held progressive management, director and executive leadership roles over his finance department tenure.

“All three of these candidates have impressive long-term records of contributing to Bradley’s success and are valuable assets to our organization,” said Luis de Leon, Bradley Corp.’s president and chief operating officer. “Their dedication and expertise position Bradley for another 100 years of growth.”

Aquatherm tabs regional sales managers

Aquatherm announced Derek Robinson and Scott Wood have joined the company as regional sales managers.

Robinson, the company’s new regional sales manager — East Coast, will be responsible for growing the company’s business in the Northeast U.S. and the East Coast to South Carolina, along with the inland states of Pennsylvania, Tennessee and parts of Kentucky. He has nearly 20 years’ experience in the plumbing and piping industry, including sales roles with some of the largest manufacturers and distributors, and has been a top performer, Aquatherm noted.

As Aquatherm’s new regional sales manager — Great Lakes region, Wood will be responsible for growing the company’s business in the Great Lakes states and upper Midwest, including Minnesota, North Dakota and South Dakota. He has more than 20 years’ experience in the plumbing and piping industry, and has also excelled in sales leader roles with some of the industry’s largest manufacturers and distributors.

“We are proud and excited to welcome Derek and Scott to Aquatherm,” said Glen Miller, Aquatherm’s vice president of sales. “They are both experienced professionals who will provide valuable expertise as we continue to grow our culture of excellence for the benefit of our customers.”

Robinson is based in Nashville, and can be reached at 615-982-4451, or derek.robinson@aquatherm.com, and Wood is based in Detroit and can be reached at 810-599-5274 or scott.wood@aquatherm.com.

Oatey relocates Texas DC

Oatey Co. announced it has relocated its Texas distribution operations to a new Irving, Texas, distribution center to further support customers throughout the greater Dallas-Fort Worth region. Previously, the company’s distribution center was located in nearby Arlington, Texas.

The Irving DC is conveniently located next to the Dallas-Fort Worth International Airport and is about twice as large as Oatey’s former facility. It has the capacity to support additional order fulfillment, equipment, parking and associate resources, including onsite conference and training rooms. The facility is also equipped with enhanced safety features, such as advanced dock sensors and a robust ventilation system.

“This exciting new distribution center positions us to meet the industry’s rapidly evolving needs, while maintaining consistent and superior service for our customers,” said John D’Ettorre, director of distribution at Oatey. “We are also pleased that the new facility offers a collaborative and productive work environment where our associates feel safe, comfortable and set up for success every day.”