A flash of inspiration

The Glitch:

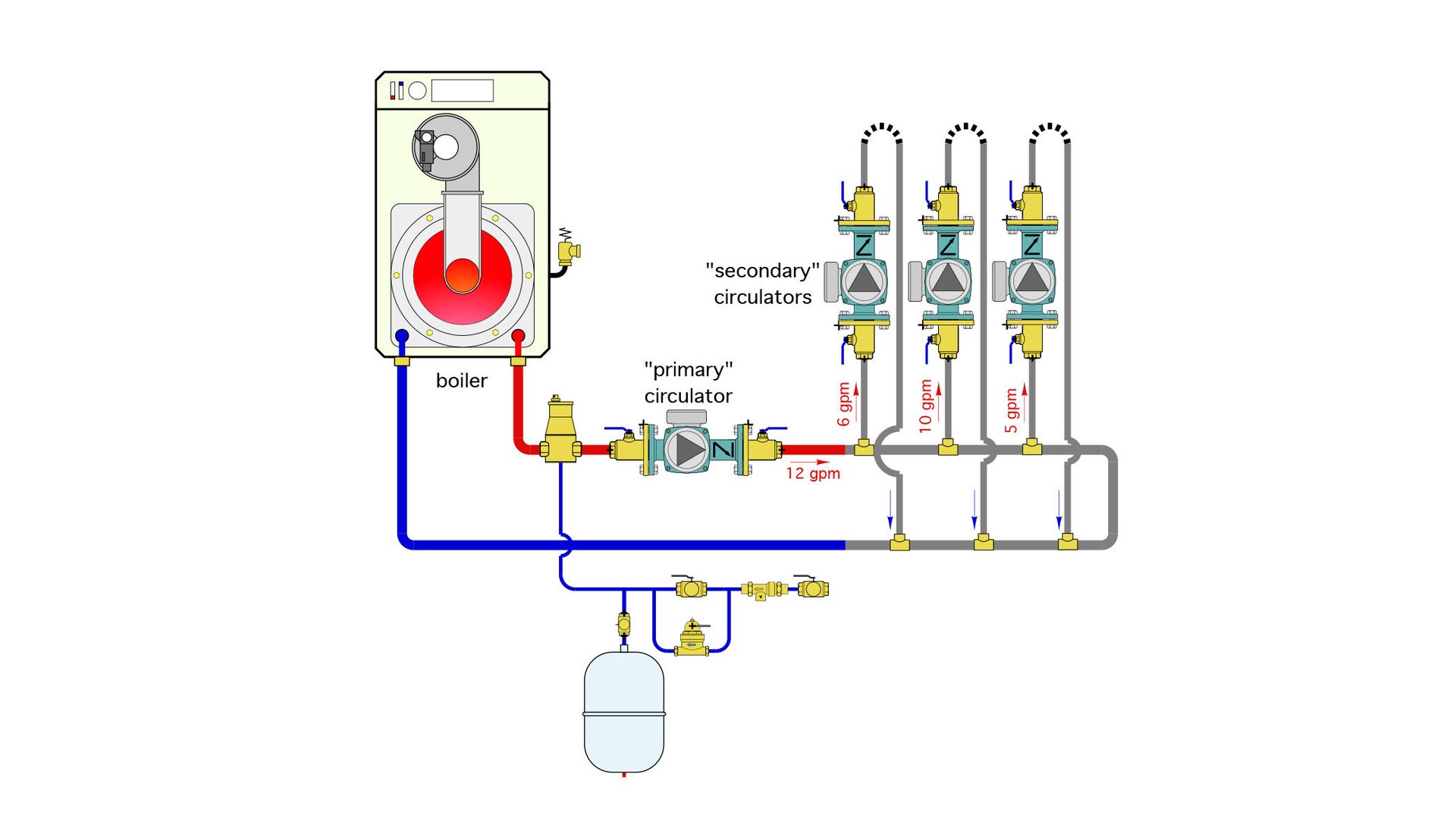

Primary/secondary systems in which pairs of closely-spaced tees (one for supply and the other for return) are installed along a piping loop provide hydraulic separation of all the circulators. However, they also create sequential temperature drops as flow in the primary loop gives up heat to each active secondary circuit.

Knowing this, an aspiring hydronics newbie decides that he can eliminate the temperature drop effect by piping a three-zone system as shown in Figure 1. The rational is that putting all three supply-side tees upstream of all three return-side tees will ensure equal supply water temperature to each of the three load circuits. Look this over and see if you’re convinced that this concept will work. If you don’t think it will work, what would you do to change it?

ENLARGE

FIGURE 1

Are you an ace troubleshooter?

Within the pages of this magazine, PM’s Hydronics Editor John Siegenthaler, P.E., will pose a question to you, our readers, to review a system’s schematic layout and discover its faults, flaws and defects. Discover archived “The Glitch & The Fix” exercises at its radiant-focused website, www.radiantandhydronics.com. Good luck!